Wood has been used as a building material for thousands of years due to its availability, low weight to strength ratio and, in many applications, high aesthetic quality. However, as a paintable substrate, it also provides some unique challenges and considerations, as wood is a dynamic, porous (cellular structure) and hygroscopic material. A few considerations include:

- Moisture content – kiln dried wood absorbs water until it reaches equilibrium with relative humidity. Moisture content can vary from about 6% to 30%.

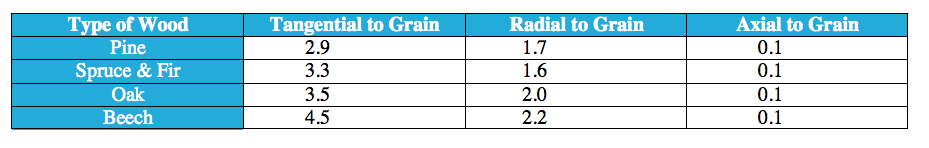

- Expansion and contraction – See Table I

- Age, wood cut geometry and type of wood – (e.g. hardwood or softwood etc.) – determines paint receptivity (moderately aged wood > new wood or very old wood)

Table I – Percent Dimensional Change of Wood as Moisture Content Varies from 5 to 15%

For a 10 cm thick wood section, a fluctuation in Relative Humidity of about 10% means a change in a tangential longitudinal wood piece of 3.5 mm (or 3,500 microns). Accordingly, these relatively large dimensional changes produce cracks as the wood looses elasticity due to aging. Thus a properly designed wood coating must have the requisite flexibility to accommodate these dimensional changes without cracking. Wood is comprised of about 75% cellulose and hemicellulose and 25% lignin, resins and low molecular weight phenolics. In exterior applications, wood is susceptible to degradation and subsequent erosion due to exposure to UV degradation, oxygen, moisture and biological activity. When exposed to the elements, the lower molecular weight materials will degrade to form water-soluble compounds that wash out whereas the more stable cellulosic molecules remain to form a white-grey color.

To read the full article about Considerations for Developing Wood Coatings, click here.

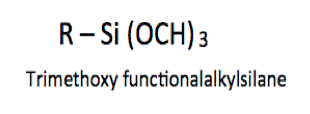

The trialkoxy silanes that are discussed in this article are those that contain primarily

The trialkoxy silanes that are discussed in this article are those that contain primarily